AI-607 M/L Aging Oven | | AI-615A AKRON Abrasion Tester |

| |  |

- JIS-K6301, ASTM-D5423

- AI-607 M/L Dumbbell specimens made by vulcanized rubber, put them inside chamber and as per different materials characteristics, standards suggest to choose 70/100/120℃, time can choose 24/48/96/168 and so on various conditions to proceed with rubber aging. Comparison the tension strength and elongation change before and after aging.

| | - JIS K6264, GB/T1689, BS-903

- The specimen of shaft speed is 76rpm which driven grinding wheel rotating about 34 rpm. The specimen outer diameter is 68mm and the thickness is 12.7mm. It cannot take round specimen it also can change thickness 3.2mm and width 12.7mm. The specimen needs to paste even on the rubber wheel to do test. The grinding wheel size: outer diameter is 150mm and thickness is 25mm and grinding wheel 36#. The specimen of shaft and wheel shaft inclined at 15 degrees and plus the normal force of the specimen 26.7N, running 16.61Km measurement volume loss; such as loss smaller than 0.1cm3 dissecting a large inclination angle of 25 degrees.

|

|

|

AI-625 Demattia Flex Crack Tester | | AI-656A Digital H.D.T. Heat Deflection Tester |

| |  |

- ASTM-D813, JIS-K6301

- For rubber, leather, synthetic leather, sole of shoes, after a constant flexing bending motion, observe the cracking lever to judge and compare the endurance of material.

| | - ASTM D648 ISO 75-1

- The specimen is given a flexion stress at the center, and the temperature should increase by 2 degrees Celsius per minute. When the specimen’s center undergoes a deflection of 0.254mm, the temperature is determined as the specimen’s deflection temperature. The tester is equipped with touch screen that guides users step by step. A user-friendly interface and standardized process are designed to orientate users in the shortest possible and to reduce test errors.

|

|

|

AI-661 Digital Vicat Heat Deflection Tester | | AI-615A DIN Abrasion Tester |

| |  |

- ASTM D1525 ISO 306 GB T1633

- The specimen is given a fixed 10N force (or 50N) at the center with a standard Ø1 mm pin, and the temperature should increase by 50 degrees Celsius per hour. When the penetration depth of specimen reaches 1mm, the temperature is determined as the Vicat softening temperature VST. The tester is equipped with touch screen that guides users step by step. A user-friendly interface and standardized process are designed to orientate users in the shortest possible and to reduce test errors.

| | - DIN53516 ISO-4649 GB/T 9867 SATRA TM174

- The is suitable for elastic material, rubber, tires, conveyor

|

|

|

AI-609A/B Discoloration Tester, Discoloration Tester (Simple type) | | AI-657B H.D.T. Heat Deflection Tester |

| |  |

- JIS-K6301, ASTM-D5423

- The AI-609A Discoloration Meter possesses oven, aging and anti-yellowing functions. A 300W UV lamp install inside the oven to simulate the fading or discoloring of sample caused by radiation of sunlight or inside high temperature containers during transportation. The AI-609B Discoloration Meter use two 15W light pipes as test irradiation source to see sample change condition through Ultraviolet ray.

| | - ASTM D648 ISO 75-1

- The specimen is given a stress at the center, and the temperature should increase by 2 degrees Celsius per minute. When the specimen’s center area reaches the deflection of 0.254mm, the temperature is determined as the specimen’s deflection temperature. The tester is equipped with touch screen. A user-friendly interface and standardized process are designed to guide users for setting operation in the shortest possible and to reduce test errors.

|

|

|

AI-640 Impact Specimen Angle Cutting Device | | AI-652S Melt Flow Index Tester |

| |  |

- JIS-K7110, ASTM-D256, ISO 179 180

- AI-640 is used to impact and then cut standard V shape notch of specimens. It can provide steadier and more accuracy result during specimen test. Notch type depend on different standards, user can select various cutter types, notch depth is adjustable conform to specimens’ requirement. Cutting speed is also adjustable to reduce the effect of specimen during cutting.

| | - ASTMD1238, D3364, ISO1133, GB- T3682

- This tester can test thermoplastic melt mass flow rate (MFR) and melt volume flow rate (MVR), AI-652S build-in ISO/ASTM standards test methods, operative picture is adopted touch panel guided conversation style screen, user can precisely and smoothly to proceed with test, build-in analysis function and with flash drive save function.

|

|

|

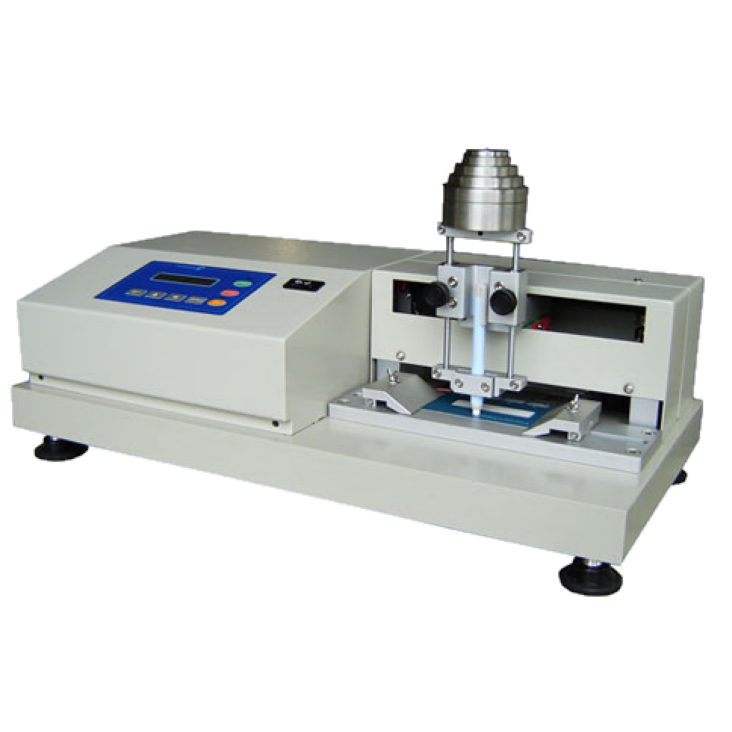

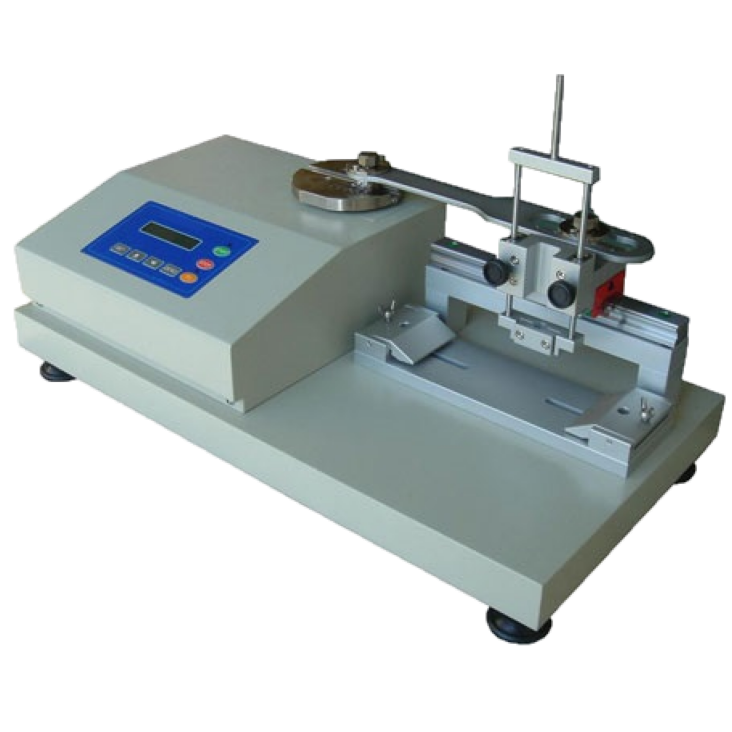

AI-621K Surface Hardness Abrasion Tester | | AI-621H Surface Hardness Abrasion Tester |

| |  |

- Its main purpose is to test surface treatment of fastness, hardness and wear resistance of characteristics. Like painting, plating, coating and dyeing of treatment of wear and fade conditions. It usually uses white cloth, sand bar, steel wool of wear specimen material. Stepper motor drive uses constant velocity friction with traditional harmonic game by test stroke limit agencies. It also can base on various standard requirements to set up test condition. Like speed, stroke, specimen shape, abrasion head type and load.

| | - This is used for measuring surface treatment such as painting, plating, coating, dyeing and finishing the design of the machine. It can use cotton, sand paper, steel wool and eraser to test specimen of wear condition. This tester can cater various different standard of requirement to set condition for testing such speed, stroke, specimen appearance, abrasion head and load.

|

|

|

AI-619K TABER Abrasion Tester | | AI-662B Vicat Heat Deflection Tester |

| |  |

- ASTM D3884, ASTM D1175, ASTM D1044, ASTM D4060, TAPPI T476, SIO 9352, ISO 5470-1, JIS K7204, JIS A1453, JIS K6902, JIS L1096, JIS K 6964, DIN 52347, DIN53109, DIN53754, DIN 53799

- AI-619K is made up of one specimen clamping disk and two grinding wheels and two vacuum nozzles, specimen clamps above disk with two wheels that can select different weights on specimens, grinding wheel diameter around 50mm, width around 13mm. Set test revolution for machine working, the nozzles will suck abrasion dust during test. Measuring specimen weight difference before and after test as specimen wear resistance properties also can be evaluated by naked eye or measure specimen thickness methods to see wear resistance condition, this machine is suitable for specimens of paper, cloth, plywood, carpet, glass, rubber and plastic materials, etc.

| | - ASTM D648 ISO 75-1

- VST (Vicat Softening Temperature) is the temperature at which the surface of a loaded specimen (1kg or 5kg) is penetrated to a depth of 1mm by a standard needle (1mm2 cross section). The temperature increases by a steady rate of 50°C per hour. The tester is equipped with touch screen that guides users step by step. During the process, the display calculates the load required by the test automatically.

|